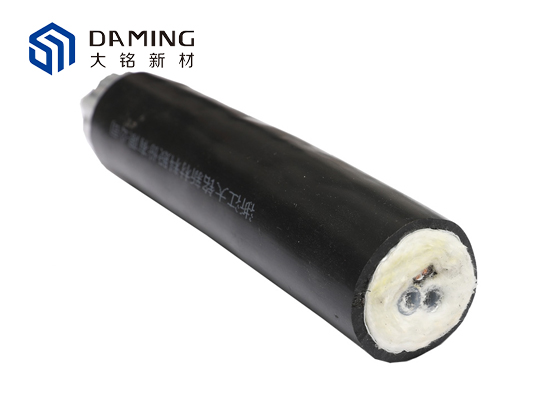

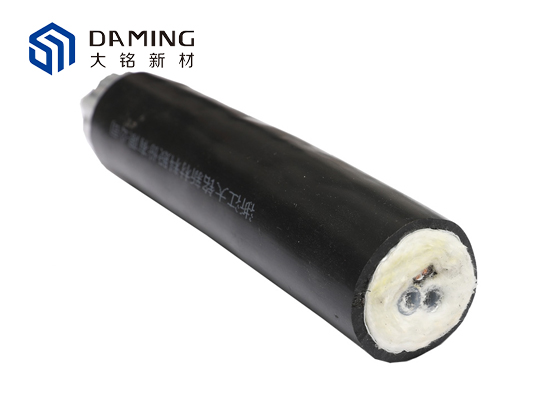

Explosion-proof anti-corrosion sampling heating composite pipe

1. Product introduction of Corrosion-Resistant Heat Tracing Sampling Composite Pipe

Anti-corrosion and heat-resistant sampling composite pipe is an important component in environmental monitoring system. It consists of a set of corrosion-resistant and high-performance resin pipe, self-limiting temperature tracking (constant power tracking) and compensation cables, external insulation layer and flame-retardant polyethylene (PE) protective sleeve. The automatic temperature limiting function of the self-limiting heating tracing belt can ensure that a certain temperature is maintained in the sampling pipeline, so as to ensure that the collected samples are consistent with the initial values as much as possible, and finally ensure that the environmental monitoring system can continuously and correctly collect sample gas. According to the actual conditions of the sample gas, such as composition and temperature, different materials can be used for the sampling pipeline in the anticorrosion and heat-resistant sampling composite pipe, such as PFA (copolymer of tetrafluoroethylene and perfluoroalkyl ether), FEP (copolymer of tetrafluoroethylene and hexafluoropropylene), PVDF (polyvinylidene fluoride), PE (flame retardant polyethylene), nylon 610, etc. The heating tracing belt can be selected according to medium, low and high temperatures, and customized according to the needs of users. This product was listed as a national key new product promotion plan in 2002, and applied for a national patent in 2001. At present, our company is one of the professional manufacturers of this kind of sampling tubes.

Corrosion-resistant and heat-tracing sampling composite pipe is a complex composed of many devices, and several systems are combined on a limited section.

● Sampling system: sampling tubes of various types and materials can be combined: Teflon PFA, FEP, nylon 610, copper tube, 316SS, 304SS, etc.

● Thermal system: efficient thermal insulation, flame retardant and lightweight insulation layer; Automatic temperature limiting heat tracing cable or constant power heat tracing cable.

● Electrical system: instrument signal cable, compensation cable and control cable can be equipped to meet the needs of instrument display and monitoring.

● Safety system: According to different technical conditions, all systems are shielded and isolated by aluminum foil or wire mesh to achieve fire prevention, anti-static and electromagnetic shielding functions. Some systems are also equipped with waterproof membranes and sheaths to enhance flame retardancy and ultraviolet protection. The combination of multiple systems integrates multiple functions and simplifies complex projects. It has played a good role in ensuring the remote work and remote diagnosis of the system. The heating tracking system can prevent the gas in the pipeline from condensing and the measured value from exceeding the dew point, thus ensuring the measurement accuracy and creating conditions for the computerization of central centralized control. The reinforced outer sheath can prevent the cross and damage affected by other factors.

2. Basic structure, classification and model of Corrosion-Resistant Heat Tracing Sampling Composite Pipe

2.1 Basic structure

The basic structure of composite pipe is shown in Figure 1.

1-outer sheath

2-insulation layer

3-Sampling tube D1

4-power cord

5-Heat tracing cable

6-Sampling tube D2

7-conductor

8-shielding reflective film

9-Compensation cable

Figure 1 Basic structure diagram

2.2 classification

2.2.1 According to the type of heat tracing cable, it can be divided into:

A) Self-temperature-limiting electric heat tracing composite pipe;

B) constant power electric tracing composite pipe.

2.2.2 According to the different sampling tube materials, it can be divided into:

A) polyvinylidene fluoride (PVDF) composite pipe;

B) Polyperfluoroethylene propylene (FEP) composite pipe;

C) soluble polytetrafluoroethylene (PFA) composite pipe;

D) polytetrafluoroethylene (ivory PTFE) composite pipe;

E) stainless steel (0Cr17Ni12Mo2) composite pipe.

2.3 model

2.3.1 The model compilation of composite pipe products shall at least include the following contents:

A) Nominal outside diameter, in millimeters (mm);

B) Outside diameter of sampling tube, in millimeters (mm);

C) Number of sampling tubes;

D) sampling tube material;

E) Operating temperature (℃);

F) Types of heat tracing cables, including self-limiting temperature electric heat tracing and constant power electric heat tracing.

3. The model representation of composite pipe is as follows:

Introduction of typical models

Example 1: The model number is FHG36-8-b-120-Z, which means that the nominal outer diameter is 36 mm, the outer diameter of the sampling tube is 8 mm, the number is 1, the material is perfluoroethylene propylene (FEP), the working temperature in the sampling tube is 120℃, and the heat tracing cable is a self-limiting composite tube.

Example 2: The model number is FHG42-10(2)-c-180-H, indicating that the nominal outer diameter is 42 mm, the outer diameter of the sampling tube is 10 mm, the number is 2, the material is soluble polytetrafluoroethylene (PFA), the working temperature in the sampling tube is 180℃, and the heating cable is a constant power composite tube.

Example 3: The model number is FHG42-8-6(2)-c-200-H, indicating that the nominal outer diameter is 42 mm, the outer diameter of sampling tube d1 is 8 mm, and the number of sampling tube d2 is 6 mm, and the sampling tube is made of soluble polytetrafluoroethylene (PFA), the working temperature in the sampling tube is 200℃, and the heat tracing cable is a constant power composite tube.

Example 4: The model number is FHG45-8(2)-6(2)-f-250-H, indicating that the nominal outer diameter is 45 mm, the outer diameter of sampling tube d1 is 8 mm, and the number is 2, and the outer diameter of sampling tube d2 is 6 mm, and the sampling tube is made of stainless steel (0Cr17Ni12Mo2), and the working temperature in the sampling tube is 250℃, with heat tracing.

Heating composite pipe